Extended Swim Platform - Page 3

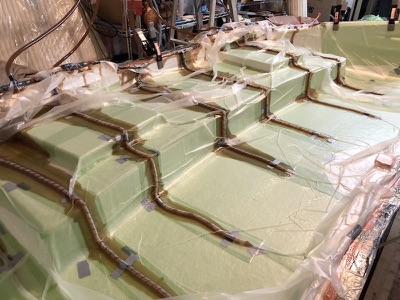

Fiberglass layup

resin infusion beginning

After much work making the mold, it was time to make the actual swim platform (from the mold). The layers of fiberglass were laid in place and then the entire mold was sealed in plastic. Resin infusion and air/vacuum tubes were attached in preparation for the resin infusion. The process of infusing this large of a part (4’ x 8’) was challenging as a rookie, so there were some adjustments made on-the-fly. In hindsight, I tried to infuse too much of the platform structure all at once and it would have been better to do a couple of infusions.

Anyway, the platform was fiberglassed and the next steps were to add the coring material, which would give it strength while not adding much weight.

The swim platform had a curved shape, matching the shape of the boat, and so the coring pieces had to be shaped accordingly. I chose to do multiple pieces of coring with fiberglass woven in between the pieces rather than a single piece of foam core. This structure is often called a ‘NAVTRUSS’ design, and I figured such a structure would be far less likely to develop delamination over the years. It would also tend to stay true to its original shape (flat).

Since the platform was curved, each piece of core had a specific location and I numbered the core pieces accordingly so as not to get them mixed up. I also molded in the 10 mounting studs that would be used to secure the platform to the boat

After the coring was fiberglassed in place, I added ‘gussets’ to the step-down area for added strength.

There was also foam coring for the aft portion of the underside to add strength to the ‘extended’ part of the platform. The foam was hand shaped and glassed, similar to the other coring sections.

The fiberglass construction of the swim platform was now done and ready to be ‘released’ from the mold. The mounting studs that are visible in the picture (left) were a combination of ‘U’ bolts and ‘J’ bolts so as to be well embedded into the fiberglass.

There were also some sidewall stiffeners added.

It took a bit of force to get the platform to ‘pop’ out of the mold, but it finally came out.

Go to the next page for a first look of the platform and the finishing steps.

foam core pieces

Aft portion foam core and glassing

platform done,

ready to release from mold