Fuel Tank Inspection

The fuel tank needed to be inspected for any signs of corrosion or other deterioration. The tank is aluminum, which has some natural resistance to oxidation, except when water is present on its surface for extended periods of time.

When water remains trapped against an aluminum tank, corrosion forms and eats away at the tank. Eventually, this could make a hole in the tank, and fuel leakage would occur. Since the boat had rot present and the tank was in close proximity to the rotted area, the tank needs to be checked out.

Here are some pictures of stripping the remaining foam off of the tank and inspecting the surfaces.

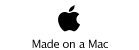

It turned out that the tank had quite a few ‘pits’ on the rear face, which butted up against the rotted bulkhead. There were also some areas of corrosion on the underside of the tank, toward the rear, where water had collected and saturated the foam.

The picture below(left) shows a close-up of the pitted areas on the end of the tank. Some of these were fairly deep, so they should be corrected. The other end of the tank as seen below (right) was in good shape as it was at the forward end of the boat where it was fairly dry.

Using foam to install aluminum fuel tanks is somewhat controversial in the boating aftermarket. Many manufacturers use foam to secure their tanks, but some marine surveyors see the residual effects of improperly installed or maintained tanks, and advise against using foam.

I contacted the Formula Boat’s Technical Support group regarding this issue. They suggested that I continue to use foam upon re-installation as a means of firmly securing the tank and maintaining structural strength. They also indicated that adding drainage would be fine if I preferred to as well. Based on my inspection of the tank, the foam that was securing the tank seemed to be fine, as long as it was kept dry.

Now it was a matter of addressing the corrosion on the tank. I had hoped to get the tank repaired, but there are few, if any welders that would repair a tank, due to many unknowns about the future longevity of the tank and the related liability. So, I decided that it was best to replace the tank entirely. After all, it is 21 years old, which is near the end of its life expectancy for marine use.

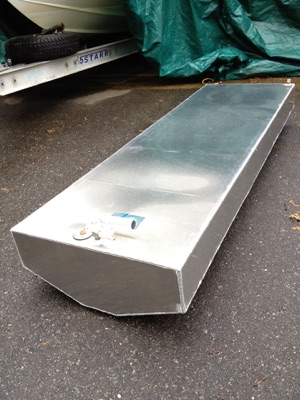

I did some Internet searching for marine tank fabricators, and it turned out that there are quite a few; some with a national reach and others more local. I priced out various suppliers and went with a local fabrication/welding company near where I keep the boat. This saved me shipping and disposal costs as I was able to drop the old tank off and could pick up the new tank.

After a couple of weeks, the tank was ready. Here are some pictures below of bringing the tank home and unloading it. The new tank is slightly smaller than the old tank and holds 85 gallons instead of the original 94 gallons.

I painted the new fuel tank with Rustoleum self-etching primer and then a top coat of appliance epoxy enamel.